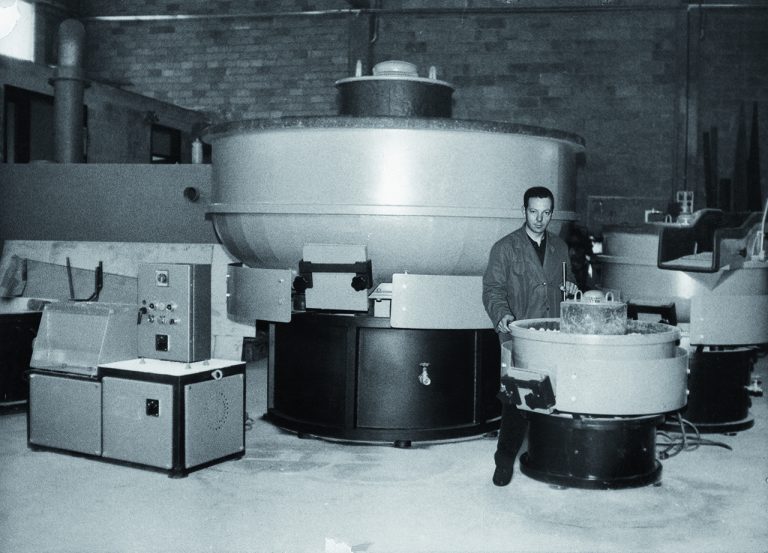

LM Industry S.R.L. was founded in 1971 by Lando Mario after gaining work experience in mechanics in Switzerland.

The business owner’s tenacity, foresight, and perseverance have allowed the company to produce over 10,000 machines, sold worldwide.

To meet the galvanization needs of the industry, Lando Mario began designing the first centrifuges, used in the same machines for the drying of galvanized parts. This sector was fertile ground for the starting up and increase of production.

In the early 1980s, the canny insight to broaden the horizons prompted Lando Mario to design and begin producing the first machines for the finishing of precious and industrial metal.

The company offered the market a comprehensive range of products for the treatment and finishing of metals, quickly becoming a reference point in the global precious-metal and industrial sectors.

In recent years, the contribution of the owner’s children has led the company to transform from artisanal to industrial. The evolution of technology has been a factor that has further promoted the modernization and production efficiency of the machines, components of advanced automatic systems built by LM and run by PLCs and cutting-edge software.

Thanks to the experience gained in the over 40 years of its history, LM recently expanded its product range by developing new technologies for the heat treatment of metals.

Sold worldwide

More than 45 years of history and experience

Continuously growing

With the desire to provide the client with an increasingly comprehensive and innovative process, LM has specialized in the production of centrifugal heating systems, furnaces for heat treatment, and applications for the foundry sector, such as ribbon burners and pre-heating systems.

All of these types of machines can be automated based on the needs of the client.

All machines are fully built on-site by the company, and the entire production process is monitored by expert technicians and trained and qualified personnel.

Our modern facility boasts carpentry, turnery, and assembly divisions as well as a warehouse and cutting-edge testing area.

The care and assistance guaranteed to our clients has earned LM high esteem and respect worldwide and in every sector.

Since 2011, LM has been managed by the founder’s three children, Walter, Doris, and Denis, and has branched out into 3 sectors:

FINISHING SYSTEMS – Smithing

CENTRIFUGAL SOLUTIONS – Centrifuges – automatic systems

FURNACES & CONVEYORS – Low- and high-temperature furnaces – automated systems

Миссия

“Больше, чем когда-либо, качество и надежность - это добавленная стоимость, на которой, одновременно с технологическим развитием, мы построили нашу историю и нацелены на будущее.”

Видение

Чтобы работать эффективно, важно стремиться достичь максимальной скорости и гибкости в развитии наших профессиональных знаний и способностей. По этой причине нашей целью является способность удовлетворить потребности наших клиентов в кратчайшие сроки с помощью наилучшего и наиболее полного решения.

Постоянно преследовать цель «абсолютного качества», заботясь о полном удовлетворении потребностей клиентов.

Сосредоточиться на постоянных исследованиях и разработке продуктов и услуг, отвечающих потребностям отрасли.

Предоставлять клиентам ответы и решения в кратчайшие сроки с помощью наилучшего и наиболее полного решения.

Чтобы гарантировать нашим клиентам постоянное развитие продукта, уделяя особое внимание надежности и практичности продукта.

Направления

LM Industry S.R.L. производит специализированное промышленное оборудование для отделки металлов в сфере обработки драгоценных металлов; центрифуги и промышленные установки для гидроэкстракции, обезжиривания и пропитки цинка; печи, печи, системы и изделия для литейного производства.